ADVANTAGES

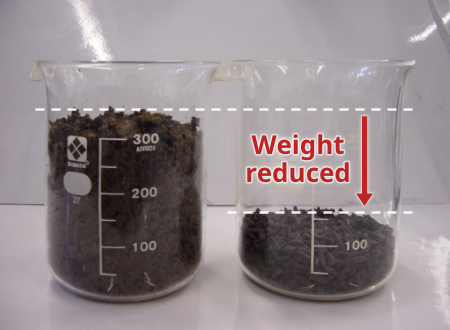

Reduces significant amount of waste sludge

By drying the dewatered cake with a water content of about 80% to the water content of 10 to 40%, the dryer significantly reduces the amount of waste sludge. Your sludge disposal cost is greatly reduced.

Water content and weight of sludge

| Sludge condition | Water content | Sludge cake weight |

|---|---|---|

| Raw sludge | 99% | 10000kg |

| Thickened sludge | 96% | 2500kg |

| Dewatered cake | 83% | 588kg |

| Dried sludge | 40% | 167kg |

| 30% | 143kg | |

| 20% | 125kg | |

| 10% | 111kg |

*Trial calculation for solid content of 100 kg-DS

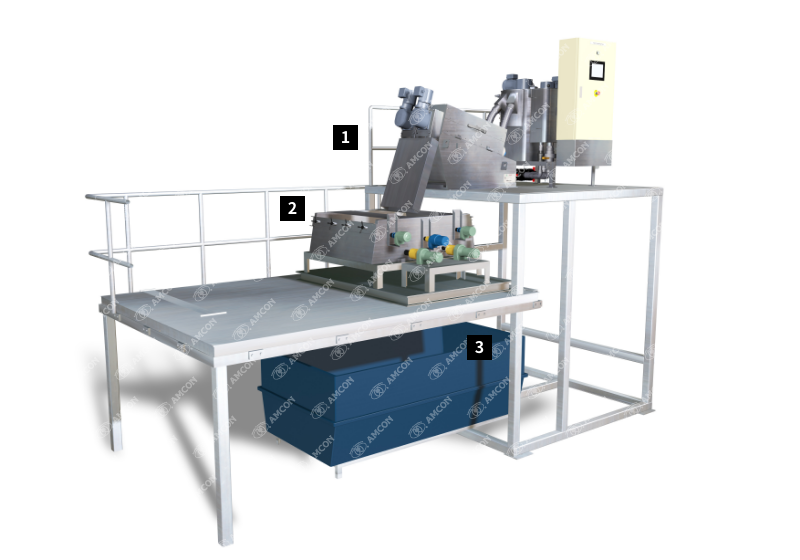

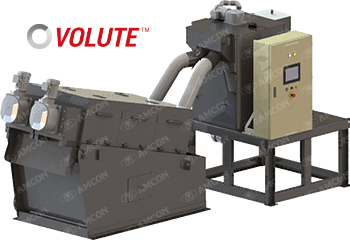

Compact design and easy installation

When combined with the VOLUTE™ Dewatering Press, the dewatered cake discharged from the dewatering machine is fed directly into the dryer which produces the dried cake continuously. Large-scale operating systems such as storage hoppers, large drying tanks, and motors are not required.

In addition, the unique double layered drum structure ensures sufficient drying area.

Its compact design makes it suitable for small facilities, and the installation is also easy.

of combined layout

PROCESS FLOW

-

01

Discharge of Dewatered Cake

The dewatered cake with a water content of about 83% discharged from the sludge dewatering press is continuously fed into the dryer. -

02

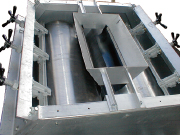

Drying Drum

The sludge is dropped onto the drum surface and then it gets dried during one rotation. -

03

Dried Cake

Dried cake with a water content of 10 to 40% is discharged.

RENTAL

Flow for Product Installation