This article introduces the role and dewatering methods of sludge dewatering machines. Additionally, it summarizes the benefits of implementing a sludge dewatering machine. We hope this article helps you in considering the imploementation of a sludge dewatering machine.

Contents

What is a Sludge Dewatering Machine?

A sludge dewatering machine is an industrial machine that dewaters sludge generated at sewage treatment plants and various industrial manufacturing plants, thereby reducing the volume of sludge to to cut down on costs and minimize the environmental impact it has on the planet. The water separated by dewatering the sludge is then returned to the wastewater treatment process and, after being treated, is released into rivers, thus returning to the natural cycle.

The Importance of Sludge Dewatering

Excess sludge produced from biological treatment typically contains over 99% water, making direct incineration or landfill disposal challenging. Dewatering the sludge transforms it into a cake-like form, simplifying its transportation, handling, and disposal.

Benefits of Using a Sludge Dewatering Machine

- Reduction of transportation and disposal costs

- Compact design maximizing the space available

- Improvement of processing efficiency

- Promotion of the reuse of waste

- Reduction of negative environmental impact

Main Applications

Sludge dewatering machines are used in various locations, such as:

- Sewage treatment plants

- Industrial waste treatment facilities

- Recycling plants

- Food and beverage manufacturing plants

- Livestock and meat processing plants

- Machinery manufacturing plants

- Chemical manufacturing plants

- Pharmaceutical factories

- Paper mills

- Apparel and textile factories

- Commercial facilities and buildings

Types of Sludge

Sludge treated by sludge dewatering machines includes the following types:

| Type | Description | Source |

|---|---|---|

| Sewage Sludge | Sludge generated at sewage treatment plants. This is a byproduct of biological and physicochemical treatment processes. | Household and commercial sewage systems |

| Industrial Sludge | Sludge generated at industrial waste treatment facilities. This type of sludge is waste from specific industrial processes. | Manufacturing, chemical plants, food factories |

| Food Sludge | Sludge generated at food processing plants. It is rich in organic matter as a byproduct of food processing. | Food processing plants |

| Chemical Sludge | Sludge generated at chemical plants. It is rich in chemical substances as a byproduct of chemical processes. | Chemical plants |

Mechanisms of Sludge Dewatering Machines

The dewatering methods of sludge dewatering machines mainly include “mechanical compression,” “centrifugal force,” and “natural drying.” Here are the features of each method:

Mechanical Compression Dewatering

Mechanical compression dewatering involves applying pressure to discharge water from the sludge.

- Use a compressor to apply high pressure and forcibly discharge water.

- Apply pressure through filter elements to separate solids and liquids.

Mechanical compression dewatering produces dewatered cakes with high solids content. The processed sludge has a moisture content of less than 85% (15%TS), making it easier to transport and dispose of.

1. Multiplate Screw Press (Sludge Dewatering Machine VOLUTE DUO™, VOLUTE™)

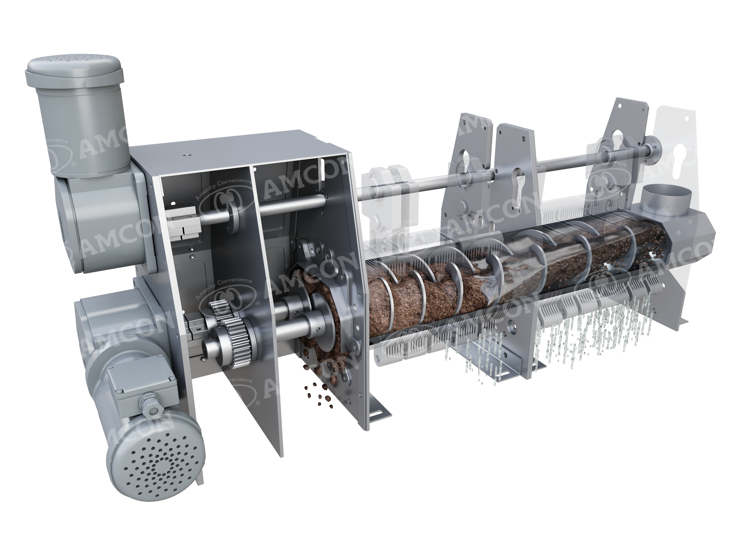

This is designed by stacking filtering rings which form a cylindrical structure which is penetrated by a screw, performing solid-liquid separation through pressure caused by the screw.

2. Screw Press Dewatering Machine

It uses filtering materials like punched metal or wedge wire with a screw structure for pressure dewatering.

3. Belt Press Dewatering Machine

It has two filtering cloths sandwiched between rollers, applying compression force through the rollers and belts to dewater the sludge.

4. Filter Press Dewatering Machine

It applies compression dewatering by pressing sludge into multiple filter chambers.

5. Multidisk Dewatering Machine: It slowly rotates stacked filtering disks, generating differential pressure between solids and liquids, causing the solids to discharge water.

Among these, the VOLUTE DUO™ and VOLUTE™ models do not require large amounts of wash water to prevent clogging and are robust for oily sludge, with minimal daily maintenance required.

For more details on VOLUTE DUO™ and VOLUTE™, click here ⇒

Centrifugal Dewatering

Centrifugal dewatering involves rotating sludge at high speeds within a device, using centrifugal force to separate the water from the sludge.

- Rotate the sludge at high speeds inside the dewatering machine.

- Centrifugal force separates and discharges water outward.

- Solids remain at the center, efficiently dewatered.

Centrifugal dewatering has a fast processing speed. For instance, a centrifugal dewatering machine can typically process several tons of sludge per hour. The rapid separation of sludge makes it especially effective for large factories and urban sewage treatment plants. However, it has drawbacks like noise, vibration, and high energy consumption.

Comparison of Mechanisms

Each dewatering method has its advantages and disadvantages.

| Dewatering Method | Advantages | Disadvantages |

|---|---|---|

| Multi-disc Screw Press (VOLUTE DUO™) | Long-life design significantly reduces replacement parts costs, and can accommodates various sludge types including oily sludge | - |

| Screw Press Dewatering Machine | Simple structure, few components | Prone to clogging, requires high-pressure wash water |

| Belt Press Dewatering Machine | Simple separation mechanism, and easy to check dewatering status | Requires a lot of high-pressure wash water, cannot dewater oily sludge, requires cloth replacement |

| Filter Press Dewatering Machine | Low moisture content, suitable for large-scale processing | Processing capacity greatly affected by sludge characteristics and inefficient batch processing |

| Multidisk Dewatering Machine | Low wash water requirement, and can dewater oily sludge | Hard to achieve low moisture content cakes, unsuitable for inorganic sludge |

| Centrifugal Dewatering Machine | Wide range of sludge types | High energy consumption, high operating costs |

Dewatered Cake

Dewatered cake refers to sludge treated by dewatering, resulting in industrial waste. Sludge is ultimately incinerated, but it must first be in a dewatered cake state before combustion.

Benefits of Implementing a Sludge Dewatering Machine

Here are the benefits of implementing a sludge dewatering machine:

Cost Reduction and Efficiency Improvement

The primary benefit is cost reduction, mainly “reducing processing costs,” “reducing labor costs,” and “reducing maintenance costs.”

- Reduction of Processing Costs: Implementing a sludge dewatering machine significantly reduces the volume of sludge to be processed, thereby cutting down transportation and disposal costs.

- Reduction of Labor Costs: Automating tasks previously done manually can reduce labor intervention, thus lowering labor costs. The VOLUTE DUO™ and VOLUTE™ models can operate continuously for 24 hours, addressing labor shortages.

- Reduction of Maintenance Costs: Regular maintenance extends the lifespan of the machine and reduces unexpected repair costs. The VOLUTE DUO™ model prevents contact between consumable parts, thereby significantly extending their lifespan and reducing replacement costs.

Reduction of Negative Environmental Impact

Dewatered sludge has a lower moisture content, and implementing a sludge dewatering machine can reduce environmental impact.

- Reduction of Waste Volume: Lowering the moisture content decreases the total waste volume, saving landfill capacity.

- Reduction of Greenhouse Gas Emissions: Reducing energy consumption during the process decreases carbon dioxide emissions.

- Reduction of Odors: Lower moisture content inhibits decay, reducing odor generation.

Conclusion

This article introduced sludge dewatering machines. These machines dewater sludge generated at sewage treatment plants and various industrial manufacturing plants, thereby reducing the sludge volume to cut down on disposal costs and minimize the environmental impact it has on the planet. Implementing a sludge dewatering machine plays a crucial role in environmental conservation and cost reduction. By understanding the types and mechanisms of such dewatering machines, you can select the appropriate machine for efficient dewatering. Consider this article as a reference when contemplating the purchase of a sludge dewatering machine.