How often and how do you maintain your sludge dewatering machine? Maintenance is a critical inspection process to maintain the lifespan of sludge dewatering machines. Without regular maintenance, the performance of sludge dewatering machines deteriorates over time, and the machine’s operation will degrade gradually. In this article, we explain in detail the necessary maintenance frequency and procedures for maintaining these essential machines.

Contents

Why the Maintenance of Sludge Dewatering Machines is Important

Sludge dewatering machines play a role in reducing industrial waste by dewatering sludge generated in wastewater treatment plants and various factory wastewater treatment facilities, thereby reducing the total volume of sludge.

Benefits of Regular Maintenance

By maintaining it regularly, the dewatering performance of sludge dewatering machines can be maintained, extending the machine’s lifespan. Furthermore, routine cleaning and planned inspections reduce the risk of sudden breakdowns and minimize downtime.

| Benefits | Details |

| Efficient Dewatering Treatment | Regular maintenance ensures the machine operates efficiently, improving the speed and quality of dewatering. |

| Stable Wastewater Treatment Operations | By preventing unexpected breakdowns, it reduces the need for repairs or replacements and ensures stable wastewater treatment. |

What is the usual lifespan of a Sludge Dewatering Machine?

The lifespan of a sludge dewatering machine largely depends on whether it was adequately maintained. Generally, the lifespan is estimated to be 10 to 15 years, but it may vary depending on the operating environment and conditions.

Here at AMCON, we have customers who have used our sludge dewatering machine, VOLUTE™, for over 25 years with proper maintenance.

Impact of Environmental Conditions

The environment where the sludge dewatering machine is installed directly affects its lifespan. For example, in environments where corrosive gases are generated or where the machine is exposed to direct sunlight, the components may deteriorate quicker.

Operating Conditions and Frequency

The frequency and load of the sludge dewatering machine’s operation also significantly affects its lifespan. Particular attention is needed when continuous operation under high load is required.

Specific Measures to Extend Lifespan

The following measures are effective in extending the lifespan of the sludge dewatering machine.

Regular Checks and Early Problem Detection

By conducting planned inspections, you can prevent major breakdowns or a sudden decline in processing capacity.

Appropriate Parts Replacement

Worn out or deteriorated parts should be replaced at an early stage to maintain the machine’s optimal performance.

Review of Operating Conditions

By reviewing the operating conditions and load, when necessary, you can ensure optimal operation and maximize the performance of the sludge dewatering machine.

Maintenance Frequency and Timing

To keep the sludge dewatering machine in a good condition, regular inspections and cleaning are essential. Here, we introduce the maintenance practices for the VOLUTE™ Dewatering Press.

Daily Maintenance Procedures

- Visual Inspection: Check the machine’s appearance and operational status.

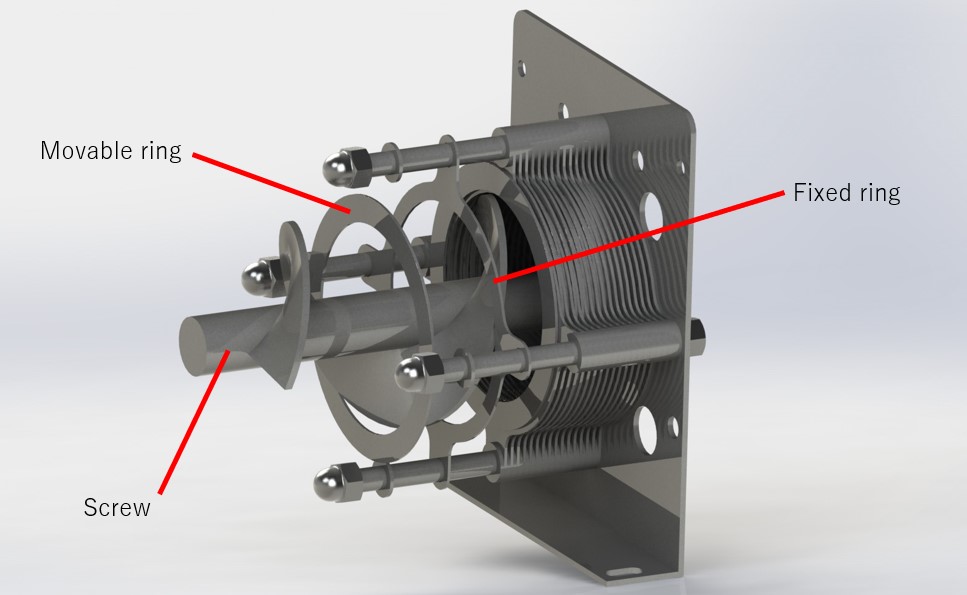

- Cylinder Unit Inspection: The cylinder unit is where the sludge is dewatered. Check for abnormal noises and ensure it is functioning properly.

- Tank Cleaning: Clean out any sludge or debris accumulated in the tanks, as it can hinder the accurate measurement of sludge input or misinterpret the sludge level.

- End Plate: Ensure it is set to the appropriate gap and that the dewatered cake is being discharged correctly. If dewatering performance (moisture content) is poor or the processing capacity has decreased, it may be necessary to replace the movable rings in the cylinder unit.

- Chemical Replenishment: If a chemical feed system is used, check the remaining amount in the chemical tank and replenish as necessary.

Monthly Maintenance Procedures

It is recommended to conduct inspections approximately once a month.

- Cylinder Unit Operation Check: The movable rings stacked within the cylinder should move up and down in sync with the screw’s rotation. Over time, this movement may become less visible due to wear and tear on the inner diameter of the movable rings or the outer diameter of the screw. As a result, the sludge processing capacity will decrease, and the dewatered cake will become looser (higher moisture content). In such cases, it is necessary to replace the movable rings or the screw.

The VOLUTE DUO™ Dewatering Press is designed to prevent contact between consumable parts such as the movable rings and screws, thereby significantly reducing the costs of consumable parts. It maintains high dewatering performance over a long period.

For more details about the VOLUTE DUO ™, click here.

- Leak Sludge Check: While some sludge may naturally leak through the gaps between rings during normal operation, if there is significantly more leakage compared to the initial operation, further checks are needed.

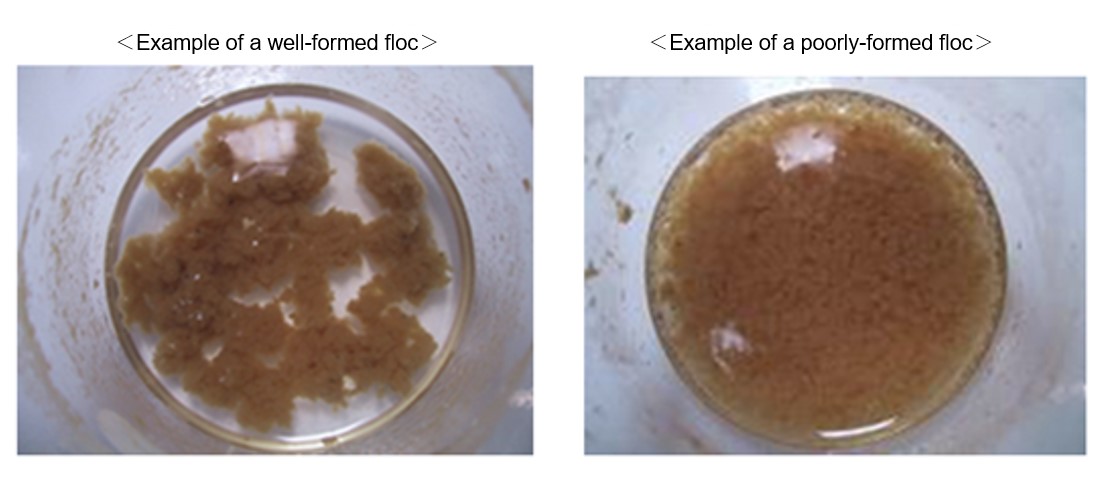

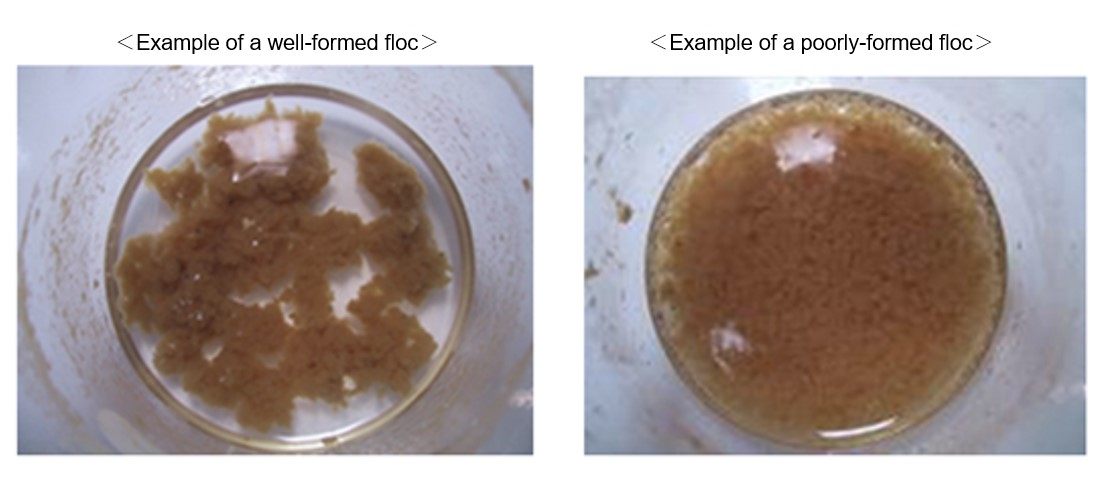

- Sludge Flocculation: The ideal size for the flocculated sludge is about the size of a pachinko ball. Confirm whether the flocculated sludge is suitable for dewatering.

2. Sludge Input Volume: Adjust the sludge input using the supplied adjustment handle, ensuring that the sludge does not exceed the electrodes in the coagulation mixing tank.

Annual Maintenance

Annual maintenance is a crucial opportunity in performing more detailed and large-scale adjustments, disassembly, and repairs. It is usually recommended to request an overhaul from the manufacturer.

- Comprehensive Operational Check: Verify that all functions are operating normally.

- Replacement of Key Components: Check the condition of critical components and replace them as necessary.

- Manufacturer Overhaul: Request a full disassembly inspection and necessary repairs from the manufacturer.

AMCON’s paid regular inspection service includes operational checks, consumable parts inspections, motor and pump checks, performance diagnostics such as processing volume, moisture content, and recovery rate, and operation adjustments. If you notice any irregularities during your daily or monthly maintenance, feel free to contact our technical service team.

For inquiries, contact us here.

Conclusion

This article has explained the importance of maintaining sludge dewatering machines. Regular maintenance is essential in extending the lifespan of the machine and to maintain its high performance. In addition to daily visual inspections and cleaning, scheduled monthly and annual maintenance can prevent deterioration of the machine. Why not review your sludge dewatering machine maintenance practices based on this article?