A must read for those who want to know more about the moisture content in sludge cake! This article provides detailed information on the mechanics of sludge dewatering machines, the benefits of lowering the moisture content, and its calculation formulas. You can even learn techniques in lowering the moisture content of your sludge, which not only contributes to the preservation of our environment, but can also significantly cut down on your operational costs.

Contents

- 1 What is the moisture content in sludge cake?

- 2 Benefits of lowering the moisture content of sludge

- 3 Relationship between the various types of sludge dewatering machines and moisture content

- 4 Methods for Measuring Moisture Content of Sludge

- 5 How to choose a sludge dewatering machine to reduce water content

- 6 Moisture content reduced by the combined usage of Polyferric sulfate

- 7 Moisture content reduction by sludge dryer

- 8 Conclusion

What is the moisture content in sludge cake?

Moisture content is an important indicator in the sludge treatment process.

It is a numerical value that expresses the weight of water as a percentage in relation to the total sludge volume, usually represented through percentages. The moisture content is a very important factor in evaluating the performance of sludge dewatering machines.

Sludge Dewatering Mechanism

Sludge dewatering machines extract water from sludge generated at sewage treatment plants and wastewater treatment facilities of various factories – to dewater the solids content.

The main purpose is to reduce disposal costs and environmental impact by reducing the bulk of the sludge, and to facilitate subsequent treatment and disposal.

- Feeding the sludge: Sludge to be treated is fed into the equipment.

- Dosing of the coagulant: Add coagulant as necessary to promote coagulation of solids.

- Compression and filtration: water is squeezed out by applying mechanical force

- Discharge dewatered cake: Discharge the solids (dehydrated cake) from which water has been removed

- Collection of filtrate: Collects the separated water (filtrate).

Benefits of lowering the moisture content of sludge

There are many benefits to lowering moisture content. Here we will discuss the three main benefits in detail.

Reduced disposal costs

Lowering the moisture content of sludge can significantly reduce treatment costs.

This is mainly due to the following factors.

- Reduced hauling costs: Lower moisture content reduces the volume and weight of the sludge, which improves the loading efficiency of hauling vehicles.

- Reduced disposal costs: Many landfills set fees based on weight, so the lower the moisture content, the lower the disposal costs.

In some cases, simply reducing the moisture content from 80% to 70% can reduce disposal costs by approximately 30%.

Reduction of environmental impact

Reducing moisture content is very important from an environmental protection perspective. There are several areas where environmental impacts are mitigated. They are as follows:

- Reduction of CO2 emissions: The distance traveled by hauling vehicles is reduced, thereby curbing fuel consumption and CO2 emissions.

- Prevention of water pollution: The higher the dewatering efficiency, the less leachate from the sludge, minimizing the impact on the surrounding environment.

- Reduced energy costs: Sludge with lower moisture content requires less energy for post dewatering-treatment, such as drying and incineration.

The promotion of reuse and recycling

Reducing the moisture content of sludge greatly expands the possibilities for reuse and recycling.

- The sludge with low moisture content can be used as a fertilizer with improved quality, making it easier to use for agriculture.

- When used as a biomass fuel, sludge with low moisture content has higher combustion efficiency, and more energy can be recovered.

Therefore, lowering the moisture content of sludge provides three major benefits: reduction of treatment costs, reduction of environmental impact, and promotion of reuse and recycling.

Relationship between the various types of sludge dewatering machines and moisture content

There are various types of sludge dewatering machines, and the moisture content depends on the characteristics of each variation. Let’s take a closer look at the four major types of sludge dewatering machines and the relation between their characteristics and moisture content.

Belt Press Dewatering Machine

This is a dewatering machine that presses the sludge between two continuous belts.

The moisture content obtained with it is usually around 70% to 85%. The moisture content will vary slightly depending on the type of sludge and operating conditions.

- Organic sludge: 75%-85%

- Inorganic sludge: 70%-80%

Centrifugal Dewatering Machine

This is a dewatering machine that uses the centrifugal force of high-speed rotation to separate solids and liquids.

The moisture content obtained by a centrifugal dewatering machine is usually around 65%-80%. Once again, this number can vary depending on the properties of the sludge and the strength of the centrifugal force.

- Organic sludge: 70%-80%

- Inorganic sludge: 65%-75%

Screw Press Dewatering Machine

Screw press dewatering machines dewater sludge by squeezing it with a rotating screw. It is characterized by its low-power operation.

The moisture content obtained with this type of machine is usually around 70% to 85%. The moisture content will vary depending on the type of sludge and the pressing force of the screw.

- Organic sludge: 75%-85%

- Inorganic sludge: 70%-80%

Multi-disc Screw Press Dewatering Machine

(sludge dewatering machines VOLUTE DUO™, VOLUTE™)

The filter consists of two types of rings stacked against each other and a screw that penetrates the inside of the filter, which performs solid-liquid separation by pressurized dewatering using the screw.

- Organic sludge: 75%-85%

- Inorganic sludge: 70%-80%

Click here for details of our VOLUTE DUO™ and VOLUTE™ sludge dewatering machines.

Simulate how much dewatering is possible! Click here for a free sample jar test.

Methods for Measuring Moisture Content of Sludge

The Moisture content is a crucial indicator in evaluating the performance of sludge dewatering machines. There are several methods in measuring moisture content, but here we introduce our drying method.

Dry method

- Sample collection: Collect a sample of approximately 10 g from the sludge and place it in an evaporating dish.

- Drying: Heat the sample at 110°C for 2 hours to dry.

- Cooling and measurement: After drying, the sample is cooled in a desiccator for 30 minutes and weighed.

- Calculation: The moisture content is calculated from the difference between the weight before and after drying, and the moisture content is reported as a percentage.

Moisture Content Formula

Moisture content is the ratio of the weight of water to the weight of the total sludge.

Moisture Content (%) = (weight of water in sludge ÷ weight of total sludge) × 100

Using this formula, the amount of water in the sludge can be expressed as a percentage.

Moisture content vs. solids concentration

Moisture content is closely related to solids concentration.

Solids concentration (%) = 100 – Moisture content (%)

In other words, as the moisture content decreases, the solids concentration increases, and vice versa.

The relation between moisture content and dewatering efficiency

When evaluating the performance of sludge dewatering equipment, dewatering efficiency is also an important indicator.

Dewatering efficiency (%) = (initial moisture content – moisture content after dewatering) ÷ initial moisture content × 100

The higher the dewatering efficiency value, the higher the performance of the dewatering machine.

How to choose a sludge dewatering machine to reduce water content

When selecting a sludge dewatering machine, several important factors should be considered to effectively reduce moisture content.

Selection by sludge properties

The properties of sludge have a significant impact on the selection of a dewatering machine. Depending on the type and characteristics of the sludge, select the appropriate dewatering machine.

Difference between organic and inorganic sludge

Sludge is broadly classified into organic and inorganic categories.

Organic sludge is mainly generated by sewage treatment plants and food factories, while inorganic sludge is generated by chemical plants, plating and surface treatment plants, power plants, and water treatment plants.

Operational costs

When selecting a new sludge dewatering machine, the subsequent operational costs are just as much a crucial factor to consider as the initial investment cost of the machine itself.

Electricity consumption study

It is important to compare the power consumption of each dewatering machine and calculate the long-term operating costs.

Centrifugal dewatering machines tend to consume relatively high amounts of electricity because they require high-speed rotation. On the other hand, belt press, screw press, and multiple plate screw press dewatering machines can operate with relatively low power consumption.

Maintenance frequency and costs

The cost and frequency of periodic maintenance must also be considered. Filter press and belt press dewatering machines require replacement of filter cloth, while screw press and multiple plate screw press types can be operated continuously and require relatively infrequent maintenance.

Moisture content reduced by the combined usage of Polyferric sulfate

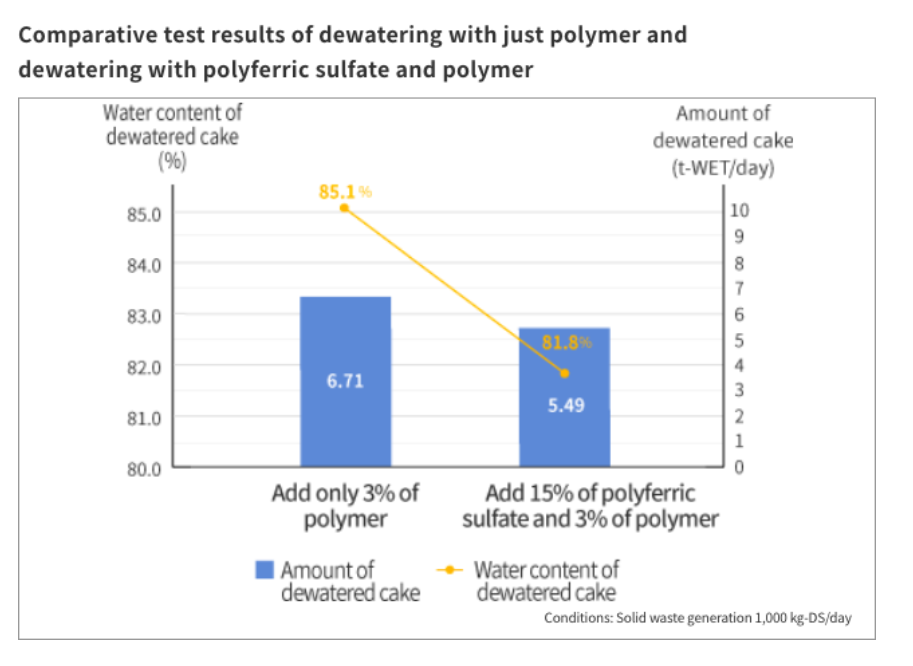

When used in combination with a polymer as a dewatering agent for waste activated sludge, the moisture content of the dewatered cake tends to decrease by 2% to 3% compared to when polymer is used alone.

The following test resulted in improved flocculation and a 3.3% point decrease in moisture content.

This will reduce waste disposal by 1.22 tons.

* This may not apply to all sludge. Please contact us for more information.

For more information about water treatment chemicals, please contact us.

Click here for details on inorganic flocculants.

Moisture content reduction by sludge dryer

After the dewatering process, the sludge can be fed into a sludge dryer to make dried sludge, thereby reducing the water content from 10% to 40%. For example, by converting dewatered sludge cake with a moisture content of 83% into dried sludge with 10% moisture content, the cake’s weight can be reduced from 588KG to 111KG (estimated for 100kg of solids – DS).

Click here for details on Electric Heat Source Sludge Dryer SP Series

Click here for consultation on the introduction of sludge dryers

Conclusion

In this article, we highlighted the significance of moisture content in sludge dewatering machines. The moisture content of sludge dewatering machines is a very important indicator in wastewater treatment. Lowering the moisture content provides benefits such as reducing treatment costs, reducing environmental impacts, and promoting recycling. There are various types of dewatering machines, such as belt press, centrifugal, and screw press types, etc. It is important to select the most suitable model depending on the properties of the sludge, treatment volume, installation space, and operational costs.

For consultation on sludge treatment, contact us here