Sludge – classified as industrial waste – must be adequately treated in accordance with Japanese law. In Japan, approximately 155.66 million tons of sludge were generated during the fiscal year of 2022, accounting for 42% of all industrial waste. However, with appropriate treatment and reuse, sludge can become a valuable resource that contributes to the sustainable reuse of resources.

In recent years, amid rising prices of chemical fertilizers, technologies that convert sewage sludge into fertilizer have garnered significant attention. In April 2023, Japan’s Ministry of Land, Infrastructure, Transport and Tourism announced a policy to promote the use of sewage sludge as fertilizer, prompting local governments and companies to accelerate their initiatives.

Reusing sludge that would otherwise be disposed of as waste not only reduces waste volume but also helps to minimize environmental impacts by decreasing the use of chemical fertilizers, thereby protecting soil and water quality.

This article explores the benefits, technologies, and practical applications of sludge fertilization in detail. * Source: Ministry of the Environment, “FY2022 Preliminary Report on Industrial Waste Generation and Treatment (Summary)”

Contents

Benefits of Using Sludge as Converted Fertilizer

Reusing sludge as fertilizer offers the following advantages:

(1) A More Economical Substitute for Chemical Fertilizers

Due to geopolitical issues such as the conflict in Ukraine and stricter inspections on Chinese fertilizer exports, the price of chemical fertilizers has soared, posing a significant burden on the agricultural sector. Fertilizers derived from sludge are more affordable and offer a stable supply, making them a cost-effective alternative.

(2) Reduction of Environmental Impact

By reusing sludge instead of disposing of it as waste, it will ultimately reduce the total amount of waste itself. Additionally, reducing the use of chemical fertilizers helps mitigate their adverse effects on soil and water quality.

(3) Soil Improvement Effects

Organic fertilizers derived from sludge are rich in organic matter and trace elements, enhancing soil moisture retention and improving aggregate structure. This contributes to long-term soil health.

Technologies for Sludge Fertilization

Proper treatment is essential prior to reusing sludge as fertilizer. Below are key technologies supporting this process:

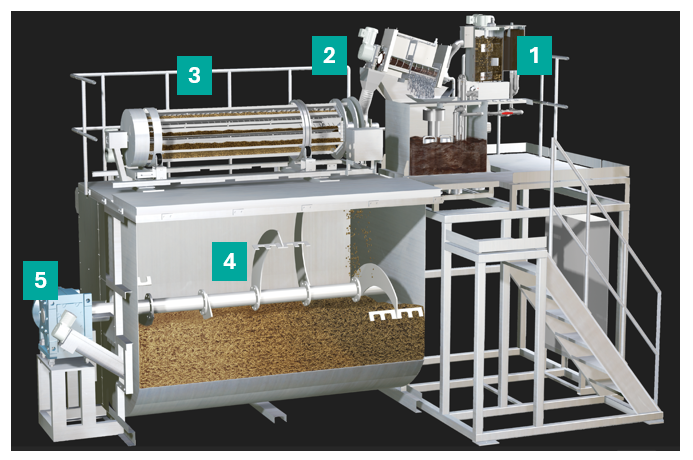

(1) Sludge Dewatering and Fermentation System “Dell Compo”

The Dell Compo system performs sludge dewatering, drying, and fermentation in a single process. The fermented sludge it produces can be used as fertilizer.

*Note: In order to use fermented sludge as fertilizer, you must first register said sludge as fertilizer.

Process Flow

Features:

- All equipment is modular, allowing for space-saving installation

- No need for additives such as sawdust or rice straw—fermentation is possible with sludge alone

- In use since 1996, mainly in agricultural wastewater treatment facilities

More about the Dell Compo, click here

(2) Sludge Dryers: “K Series” & “SP Series”

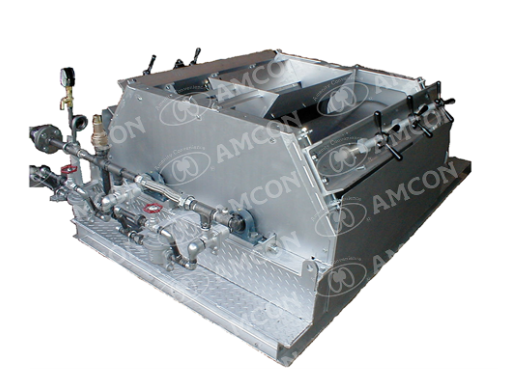

Did you know that sludge can be used as fertilizer without fermentation?

Sludge generated via activated sludge treatment in the food processing industry can be transformed into fertilizer simply through drying. Known as microbial biomass fertilizer, it is categorized differently from conventional sewage sludge-based fertilizers, eliminating safety concerns or negative impressions.

In addition to the food industry, sludge from pulp, fermentation, or gelatin production (excluding those using leather waste) can also be used for fertilizer production.

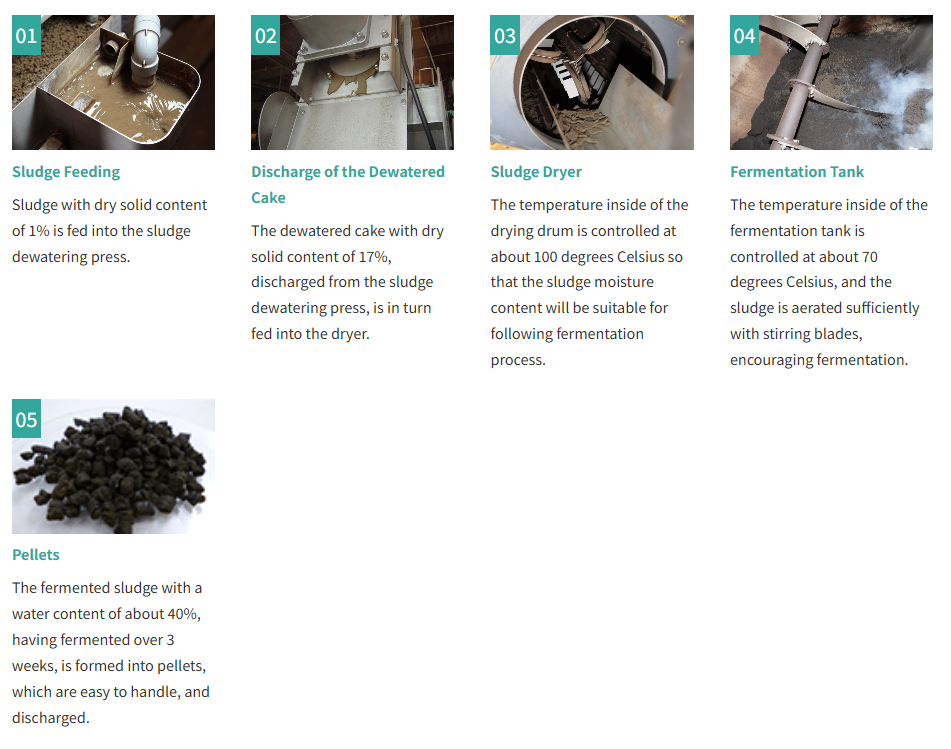

K Series Sludge Dryer (Steam-Powered Drum Type)

Using steam as its heat source, the dryer is fed sludge between two rotating drums where it adheres to the drums’ surface to dry in a thin film.

Advantages:

- Simple structure for easy maintenance

- No need for large-scale equipment such as storage hoppers, large drying tanks, or motors

- Compact size suitable for small facilities

More about the K Series, click here

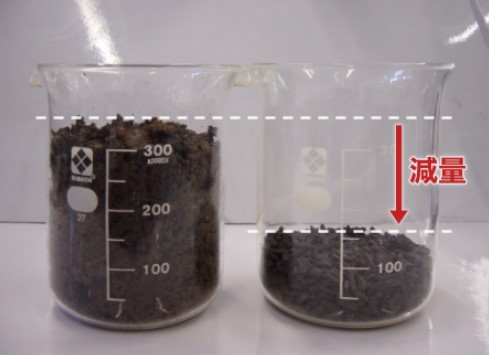

SP Series Sludge Dryer (Electric Rotary Kiln Type)

This compact dryer features a proprietary dual-drum structure.

Advantages:

- Dried sludge is discharged continuously in flake form, reducing dust and simplifying handling

- Small and easy to install

- No need for large-scale equipment such as storage hoppers, large drying tanks, or motors

More about the SP Series, click here

When combined with our VOLUTE™ sludge dewatering press, the dewatered sludge cake can be fed directly into either the K Series or SP Series dryer, enabling continuous drying and discharge.

Cost Reduction for Physico-Chemically Treated Sludge

Some sludge undergoes physicochemical treatments, such as chemical-sedimentation, and cannot be used as fertilizer. However, by drying it out to a moisture content of sub-40% can significantly reduce industrial waste disposal costs.

Conclusion

Fertilizing with sludge offers numerous benefits, including waste reduction, lower agricultural costs, and reduced environmental impact. Especially in today’s climate of rising fertilizer prices, sludge-based fertilizers may hold the key to sustainable agriculture. If you are interested in the Dell Compo sludge fermentation system or the K Series and SP Series sludge dryers, please feel free to contact us.

For inquiries, contact us here